How Common Rail Injection Works

Hi everyone. Today I found a great article in Diesel Hub that I know many of you will enjoy reading or possibly relate to. The original article can be found here - http://www.dieselhub.com/tech/common-rail.html - if you’d like to read the article there, or I’ve pasted parts of it here to share it. It’s well worth a read.

The high pressure common rail is the injection type of choice for modern diesel engines, far surpassing the capabilities of mechanical and hydraulic injection systems of years past. Due to relatively high injection pressures and greater control over injector events, common rail injection systems feature favorable performance characteristics and lower emissions.

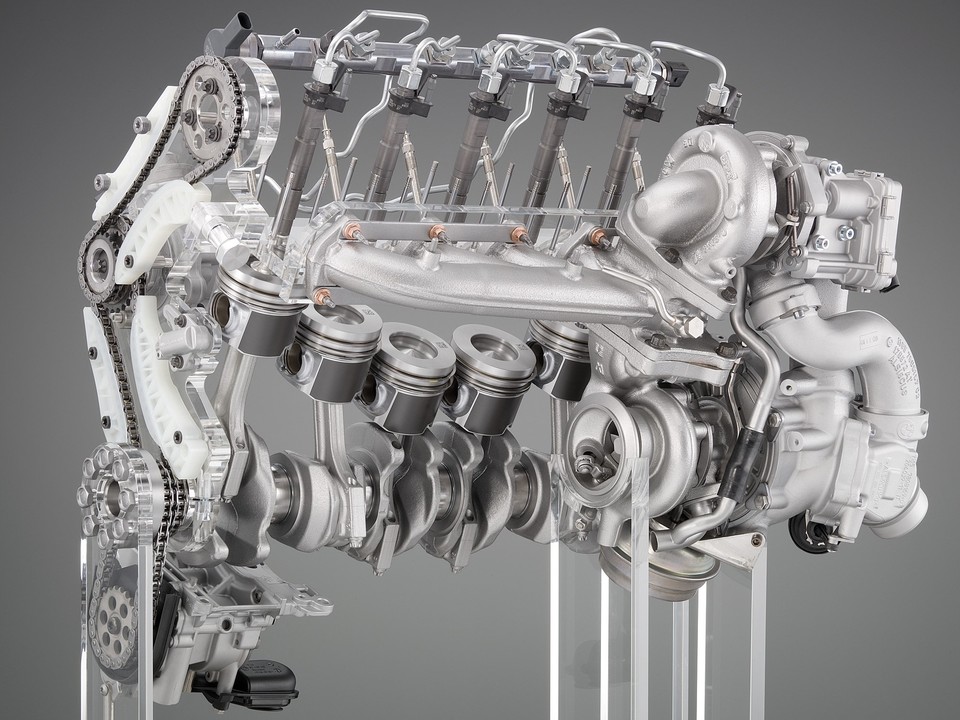

High pressure common rail injection systems, or simply common rails, are the injection type of choice for modern diesel engines. The configurations superior performance characteristics and relatively high injection pressures reduce emissions while improving efficiency. A common rail system is comprised of a low pressure fuel pump (lift pump), high pressure fuel pump (injection pump), Piezo electric fuel injectors, and the associated rail system.

Fuel is delivered from the fuel tank to the injection pump via the lift pump. The lift pump's only purpose is to consistently provide fuel to the injection pump - the pressure of the fuel as it enters the injection pump is small and has no effect on the actual injection pressure. The high pressure pump maintains tremendous pressure within the common rail(s); an I-6 engine features a single common rail that feeds each injector, while a "V" engine will utilize two common rails, one for each engine bank. The "rail pressure", or pressure of the fuel system at the outlet of the high pressure pump, can reach pressures in excess of 30,000 psi.

Injection events are commanded by the PCM/ECM, which energizes an injector in order to initiate an injector event. When this occurs, fuel flows through the injector nozzle where it atomizes as it enters the combustion chamber. The most important factor in a common rail system is rail pressure; greater rail pressure yields greater atomization of fuel and is therefore closely related with combustion efficiency.

The common rail system is an alternative to mechanical injection pumps and HEUI systems, both of which lack the inherent ability to realize higher injection pressures and the ability to fire an injector multiple times per single combustion event. This translates into greater performance potential, lower particulate emissions, and greater efficiency. Common rail injection types also typically reduce engine noise.

All generations of the 6.6L Duramax diesel employ a high pressure common rail injection system. The 5.9L Cummins was upgraded to a common rail system for the 2003 model year (24v model), and both International's 6.4L and Ford's 6.7L Power Stroke feature common rail systems.

This author seems to write some great stuff and well worth following. If there is any other info you’d like me to search out and share in the world of Mechanical/Industrial Engineering then please let me know, or feel free to reach out on (0403) 243-786.

Thanks,

Matthew

Owner of problem solving businesses in automation and quality inspection

3yGreat article. Our company makes, among other things, automated dimensional inspection systems, and have an installed base for brazed fuel rail inspection machines across a number of leading common rail manufacturers. Seeing an increase in demand for forged common rail inspection has us doing our homework. Appreciate the information, Matthew!